Advantages of Investing in a Continuous Plastic Pyrolysis Plant

- Feb 16, 2025

- 4 min read

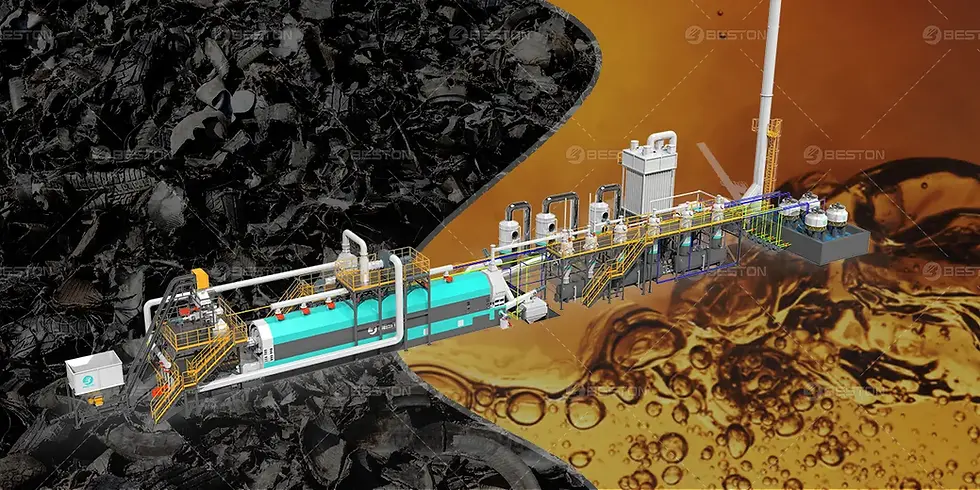

The rise in plastic waste generation has sparked a global push toward sustainable waste management practices. Among the most promising solutions to this issue is plastic pyrolysis, a process that converts plastic waste into valuable by-products such as bio-oil, carbon black, and syngas. In particular, the continuous plastic pyrolysis plant offers significant advantages over traditional batch processing systems. These benefits include enhanced efficiency, higher product yield, and long-term economic sustainability. This article examines why investing in a continuous plastic pyrolysis plant can be a highly profitable and environmentally beneficial decision.

High Throughput and Continuous Operation

One of the most significant advantages of a continuous plastic pyrolysis plant is its ability to operate non-stop. Unlike batch systems, which require intermittent loading and unloading of feedstock, continuous systems are designed for uninterrupted processing. This leads to higher throughput and more consistent product output, resulting in improved operational efficiency. For businesses, this means a steadier production rate and the potential for scaling operations to meet growing market demand.

In a continuous system, plastic waste is fed into the reactor at a constant rate, ensuring that the pyrolysis process runs smoothly and continuously. As a result, businesses can maximize the utilization of their resources, reducing idle time and increasing the overall productivity of the plant. This steady operation not only improves output but also reduces the time and labor needed for plant operation, which translates to lower operational costs.

Cost Efficiency and Energy Savings

The investment required for a continuous plastic to oil plant is offset by the long-term savings in both operational and maintenance costs. These systems are generally more cost-effective than batch reactors due to their higher efficiency and reduced energy consumption. In a continuous system, the reaction chamber maintains a consistent temperature and pressure, optimizing energy usage and reducing fuel requirements.

Additionally, the pyrolysis process generates valuable by-products such as syngas, which can be used to fuel the plant's own operations. By recycling the syngas back into the reactor, the plant can significantly reduce its reliance on external energy sources, further lowering operating expenses. This energy-efficient approach also makes continuous pyrolysis systems more sustainable and cost-effective in the long run.

Better Product Quality and Yield

Continuous plastic pyrolysis plants are optimized to produce a higher yield of bio-oil, carbon black, and syngas, with a more consistent quality across batches. The precision with which these plants maintain process variables such as temperature, pressure, and feedstock ratio ensures that the end products meet high-quality standards. In contrast, batch reactors often experience variability in the product output, which can negatively affect the marketability of the by-products.

Moreover, the steady operation of a continuous system reduces the likelihood of process disruptions that may lead to the degradation of the final products. This results in a higher quality of bio-oil, which can be used as a renewable energy source or further refined for industrial applications. Carbon black produced from continuous pyrolysis is also more consistent and can be used in various industries, including rubber manufacturing, ink production, and even agriculture.

Environmental Benefits and Sustainability

Investing in a continuous plastic pyrolysis plant also aligns with global sustainability goals. Plastic waste has become one of the most significant environmental challenges of the modern era, with millions of tons of plastic discarded each year. The pyrolysis process offers a solution by converting plastic waste into useful products, reducing the need for landfills and minimizing environmental pollution.

By continuously processing plastic waste into valuable by-products, these plants contribute to the circular economy, where waste is repurposed as a resource. This helps to reduce the demand for virgin materials, cutting down on the environmental impact of traditional manufacturing processes. Furthermore, the carbon black produced through pyrolysis can be used as a soil amendment, contributing to soil health and further enhancing the plant's environmental credentials.

Scalability and Flexibility

One of the key features of a continuous plastic pyrolysis plant is its scalability. As demand for plastic recycling and waste-to-energy solutions grows, businesses can easily scale their operations by adding more reactors or increasing the capacity of existing systems. The flexibility of continuous pyrolysis plants makes them suitable for both small-scale operations and large industrial applications, allowing businesses to tailor the system to meet specific production needs.

This scalability also offers opportunities for businesses to diversify their revenue streams. For example, bio-oil can be sold as a renewable fuel, while carbon black can be marketed to the manufacturing and agricultural sectors. Syngas can be utilized for energy generation, and any excess can be sold to the local energy grid. The ability to adapt the system to different markets and by-products increases the plant's profitability and long-term viability.

Competitive Edge in a Growing Market

The global demand for sustainable waste management solutions is increasing as governments and industries seek to reduce their carbon footprint and minimize plastic waste. A continuous plastic pyrolysis plant positions businesses to capitalize on this growing trend. By offering a consistent and reliable process for converting plastic waste into valuable products, companies can gain a competitive edge in the recycling and waste-to-energy markets.

Furthermore, the ability to offer eco-friendly products such as bio-oil and carbon black aligns with the increasing consumer preference for sustainable and environmentally conscious products. Businesses that invest in continuous pyrolysis technology can not only meet regulatory requirements but also enhance their brand reputation by contributing to the reduction of plastic waste and the promotion of circular economy practices.

Comments