Converting Oil Sludge into Value: The Role of Pyrolysis Technology

- Jun 4, 2025

- 3 min read

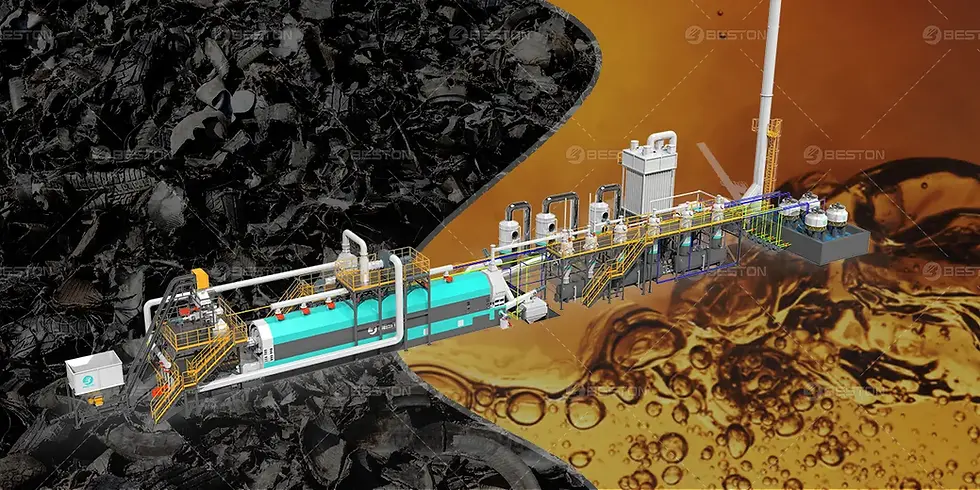

Oil sludge, a hazardous by-product generated from petroleum refining, storage, and transportation, presents a formidable environmental challenge. Characterized by its high viscosity, complex composition, and pollutant potential, untreated oil sludge can contaminate soil and groundwater for decades. However, recent advancements in thermal decomposition technology—specifically pyrolysis—are offering a viable route for resource recovery and environmental mitigation.

Composition and Challenges of Oil Sludge

Oil sludge is a heterogenous mixture composed of water, petroleum hydrocarbons, heavy metals, and solid particulates. Its composition varies depending on the source, such as refinery bottom tanks, oil-water separators, or drilling operations. Conventional treatment methods, including incineration, solidification, or landfill disposal, are often energy-intensive, costly, and environmentally unsustainable. They typically result in material loss and generate secondary pollutants.

To address this, pyrolysis has emerged as a closed-loop, waste-to-resource process that thermochemically decomposes oil sludge into reusable products under an oxygen-deprived atmosphere.

Mechanism of Pyrolytic Conversion

An oil sludge pyrolysis plant operating on oil sludge employs high-temperature processing—typically between 450°C and 600°C—under inert or low-oxygen conditions. The heat breaks down long-chain petroleum hydrocarbons into shorter molecular compounds. Water and volatiles are driven off, heavy metals remain in the residue, and the organic fraction is transformed into pyrolysis oil, combustible gas, and solid char.

The reaction does not involve combustion, thus avoiding dioxin formation and reducing air pollutants. Furthermore, the non-condensable gases produced can be recirculated as a heating source, making the process partially self-sustaining.

Key Outputs from Oil Sludge Pyrolysis

A well-optimized thermal desorption unit can recover three core products from oil sludge:

Pyrolysis oil: A dark, viscous liquid with significant calorific value. It can be further refined for use as boiler fuel or as a precursor for industrial heating applications.

Non-condensable gas: Comprising light hydrocarbons such as methane, ethane, and hydrogen, this gas can be combusted on-site to provide thermal energy for the reactor itself.

Solid residue: A stable char that may contain metal oxides and inorganic ash. With appropriate treatment, this residue can be stabilized or repurposed in construction materials or road base applications.

This triform output structure enables comprehensive material recovery and drastically reduces the volume of final waste.

Advantages Over Traditional Treatment

Compared to incineration or landfilling, pyrolysis provides several distinct advantages:

Volume reduction: Pyrolysis decreases oil sludge volume by up to 90%, minimizing disposal requirements.

Energy recovery: The calorific value of pyrolysis oil and gas provides an energy-positive operation.

Pollution control: Enclosed systems equipped with scrubbers and condensers ensure minimal emissions, making it compliant with international environmental standards.

Economic potential: Recovered oil can be monetized, reducing the overall treatment cost and enabling long-term ROI for operators.

These advantages position the pyrolysis plant as an environmentally and economically favorable solution for oil sludge remediation.

System Design and Integration Considerations

Designing an effective pyrolysis plant for oil sludge requires attention to feedstock characteristics, moisture content, and contaminant profile. Pre-treatment steps—such as dewatering, homogenization, and emulsified oil separation—can significantly enhance reactor efficiency and output quality.

Furthermore, integrating the pyrolysis system with upstream and downstream processes, including oil-water separation and residue stabilization, creates a holistic waste management chain. Continuous feed systems and PLC-controlled operations ensure stable thermal conditions and optimal material throughput.

Advanced configurations may also include energy recovery loops, gas scrubbing units, and post-treatment modules for oil upgrading. Such modular design allows the pyrolysis plant to adapt to varying operational scales and regulatory frameworks.

Comments