Maximizing Profit from Tire Pyrolysis Projects

- Mar 14, 2025

- 4 min read

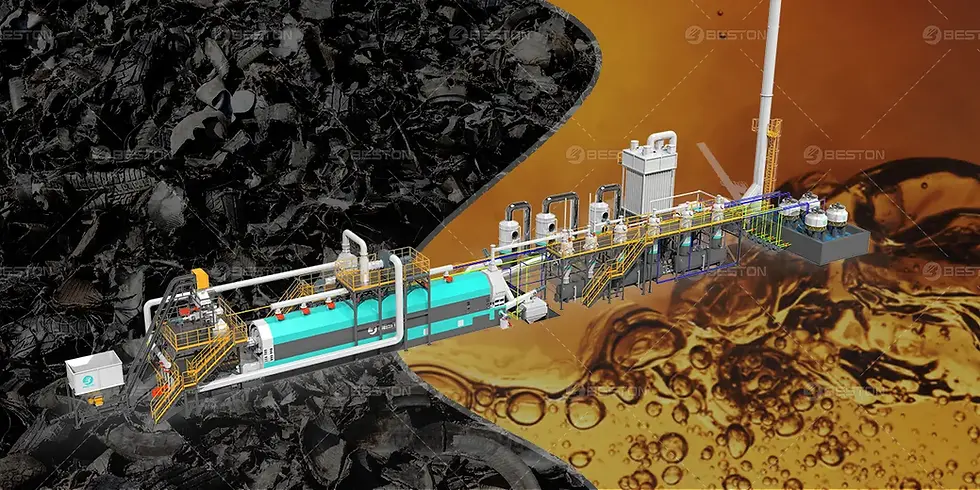

The tire pyrolysis project has emerged as a promising business venture due to its potential to transform waste tires into valuable by-products, including bio-oil, carbon black, and syngas. By utilizing a pyrolysis plant, businesses can not only contribute to the solution of the global waste tire crisis but also tap into multiple revenue streams. However, achieving profitability from such a project requires a careful approach that balances initial investment, operational costs, and the efficient use of by-products. This article examines key strategies to ensure a tire pyrolysis project generates substantial returns.

Investment in High-Quality Pyrolysis Equipment

The first step toward a profitable tire pyrolysis machine begins with selecting the right equipment. A well-built pyrolysis plant capable of handling the high temperature and pressure conditions required for tire pyrolysis is crucial. Efficiency in energy consumption and maximizing the yield of usable by-products are essential for ensuring that the project remains profitable. While the initial pyrolysis plant cost might be significant, investing in high-quality machinery can lead to long-term savings by reducing maintenance and increasing output.

Capacity and Throughput: Opting for a pyrolysis plant with the appropriate processing capacity is key. A plant that can process a high volume of tires per day will result in greater production rates of bio-oil, carbon black, and syngas. Balancing this capacity with the available feedstock is necessary to prevent underutilization, which could negatively impact profitability.

Automation and Control Systems: The integration of automated control systems can significantly reduce labor costs and enhance operational efficiency. Automated systems for feedstock input, temperature control, and product collection minimize human error and improve the consistency of the final products. As a result, businesses can reduce the costs associated with manual labor and boost the overall profitability of the project.

Optimizing By-Product Management

One of the most lucrative aspects of a tyre oil plant is its ability to generate multiple valuable by-products, each of which can be sold or further refined. Maximizing the value of these by-products is essential to increasing profitability.

Bio-Oil: The liquid produced during tire pyrolysis, known as bio-oil, can be processed into various fuels or chemicals. Bio-oil can be used as a substitute for diesel in industrial processes, power generation, or even refined into higher-value products like light fuel oils. The market for bio-oil is growing due to its potential as a renewable energy source, and by tapping into this demand, businesses can generate a steady revenue stream.

Carbon Black: The carbon black produced from tire pyrolysis is a versatile product with applications in industries such as rubber manufacturing, plastics, and batteries. By ensuring that the carbon black meets the quality standards required by these industries, businesses can command higher prices for the product. Additionally, companies can explore value-added applications such as producing activated carbon, which is in demand for water filtration and air purification systems.

Syngas: The gases released during the pyrolysis process, collectively known as syngas, can be utilized as an energy source to power the pyrolysis plant itself. This reduces reliance on external electricity supplies and lowers operating costs. Any surplus syngas can be sold to local power plants or industries in need of energy, providing another profitable avenue for businesses engaged in tire pyrolysis.

Reducing Operational Costs

Although the potential for high profits in tire pyrolysis is significant, reducing operational costs is essential for ensuring long-term profitability. Several strategies can be employed to minimize expenses, both during the production process and throughout the lifecycle of the plant.

Energy Efficiency: Tire pyrolysis is an energy-intensive process. However, with effective energy management, businesses can offset some of these costs. Utilizing syngas for internal energy needs significantly reduces external fuel consumption, lowering the overall operational cost. Additionally, optimizing heat recovery systems can increase the overall efficiency of the pyrolysis plant, further reducing energy expenditure.

Waste Heat Utilization: The heat generated during the pyrolysis process can be used to preheat incoming feedstock or generate steam for other industrial applications. By capturing and reusing waste heat, businesses can further reduce energy costs while increasing plant efficiency.

Preventive Maintenance: Proper maintenance of the pyrolysis plant equipment can prevent costly repairs and extend the lifespan of machinery. Regularly inspecting and servicing the reactor, burner system, and gas cleaning equipment ensures that the plant operates at peak efficiency, minimizing unexpected downtime and increasing productivity.

Expanding Revenue Through Value-Added Products

In addition to the core by-products of bio-oil, carbon black, and syngas, businesses can explore the production of value-added products to further boost profits. For example, by upgrading bio-oil into higher-grade fuels or refining carbon black into activated carbon, companies can sell products at a premium price.

Upgrading Bio-Oil: Bio-oil from the pyrolysis process is typically not suitable for direct use in all applications due to its impurities. However, it can be further refined through distillation or other chemical processes to produce higher-value products like transportation fuels, which are in high demand as an alternative to fossil fuels.

Carbon Black Refinement: The carbon black produced during tire pyrolysis is often raw and unrefined. By processing it into activated carbon, it can be marketed to industries involved in water and air purification, where high-quality carbon black is essential.

Diversifying Feedstock: While tire pyrolysis is the core business model, diversifying the feedstock can further increase the plant's profitability. Accepting other types of waste rubber, plastics, and biomass can help maximize the utilization of the pyrolysis reactor, thereby increasing output and revenue.

Targeting Market Demand

Maximizing profit from a tire pyrolysis project also involves understanding and targeting the right market. Each by-product of the pyrolysis process has its own market with specific demand.

Renewable Energy Sector: Bio-oil and syngas are highly sought after in the renewable energy sector. By positioning these products as sustainable alternatives to fossil fuels, businesses can tap into growing demand from industries seeking to reduce their carbon footprint.

Rubber and Plastics Industries: Carbon black is an essential ingredient in rubber manufacturing, making it a valuable product for industries like automotive tire production and plastics. Establishing connections with these industries can ensure a steady market for carbon black.

Waste Management Companies: As governments increasingly regulate tire disposal, partnerships with waste management companies can help secure a steady supply of used tires. These companies often seek environmentally responsible methods for recycling tires, and pyrolysis provides a sustainable solution.

Comments