The Growing Market for Continuous Tire Pyrolysis Equipment

- Jul 8, 2025

- 3 min read

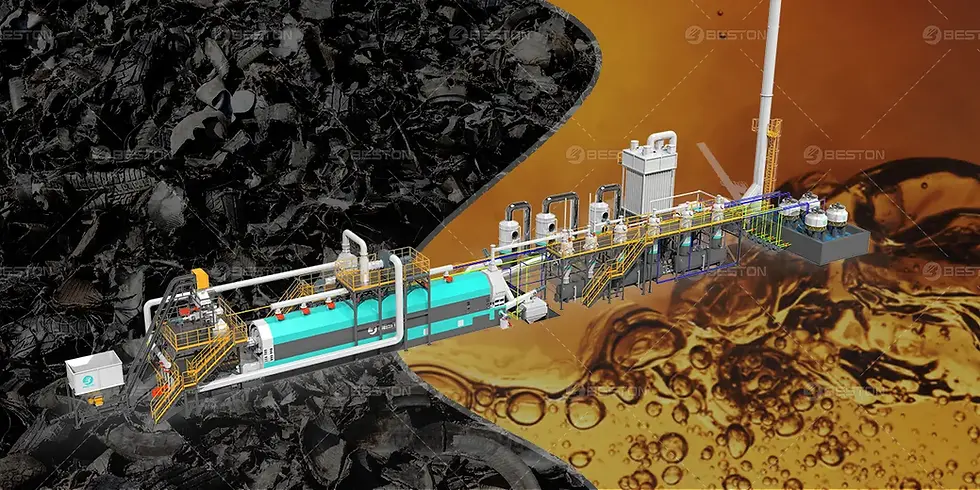

The demand for tire pyrolysis equipment has grown rapidly in recent years due to increasing environmental concerns and the need for sustainable waste management solutions. Among various types of pyrolysis technology, continuous tire pyrolysis equipment has garnered significant attention for its efficiency and scalability. As the world grapples with the escalating problem of tire waste, the market potential of this technology presents both environmental and economic opportunities.

Rising Demand for Tire Recycling Solutions

The global tire recycling market has been expanding as governments and industries face mounting pressure to reduce waste and adopt circular economy practices. With billions of tires being discarded each year, the potential for tire pyrolysis plant to address this issue is considerable. These plants offer an innovative solution that not only addresses the environmental burden of tire disposal but also produces valuable products like oil, carbon black, and steel wire.

Tires are a complex material composed of various substances, including rubber, carbon black, and steel, making their disposal challenging. Traditional disposal methods, such as landfilling or incineration, often pose environmental risks, including soil contamination and air pollution. In contrast, pyrolysis provides an efficient and eco-friendly method for converting waste tires into useful by-products.

Economic Benefits of Continuous Pyrolysis Technology

The continuous tyre pyrolysis plant is designed for large-scale operations, which allows it to achieve higher throughput compared to batch systems. This scalability makes it an attractive option for both large and small businesses looking to capitalize on the growing demand for tire recycling.

One of the most significant advantages of continuous tire pyrolysis is its ability to operate non-stop, maximizing productivity and minimizing downtime. The steady output of pyrolyzed oil, carbon black, and steel wire contributes to multiple revenue streams, enhancing the profitability of the business. Pyrolysis oil, for example, can be used as an alternative fuel in various industries, such as power generation, while carbon black is a valuable material in the production of new tires and other rubber products.

Moreover, the continuous nature of the process leads to improved energy efficiency, reducing operating costs. This is a key factor for businesses seeking to enhance their bottom line while contributing to environmental sustainability.

Technological Advancements in Continuous Tire Pyrolysis

The continuous tire pyrolysis plant has evolved significantly with advancements in pyrolysis technology. Modern plants are equipped with automated control systems, which ensure precise temperature regulation and optimal reaction conditions for tire pyrolysis. This not only enhances the efficiency of the process but also improves the quality and consistency of the output products.

Recent innovations have also focused on reducing emissions, a critical consideration for industries concerned with regulatory compliance. State-of-the-art continuous pyrolysis systems feature advanced gas cleaning and filtration technologies that minimize harmful emissions, ensuring compliance with stringent environmental standards. This makes them suitable for deployment in regions with strict environmental regulations, further expanding their market potential.

Additionally, some plants now offer integrated systems for the recycling of gases produced during the pyrolysis process, enhancing sustainability. These gases can be captured and converted into energy, reducing reliance on external fuel sources and making the entire process more self-sustaining.

Market Expansion and Global Opportunities

The market for continuous tire pyrolysis equipment is not confined to any single region. In fact, the growing awareness of tire waste management and sustainable solutions has led to increased demand across emerging markets in Asia, Africa, and Latin America.

In developing regions, rapid industrialization and urbanization have led to higher vehicle ownership and, consequently, greater tire waste. These regions are particularly well-positioned to benefit from tire pyrolysis technologies, as they struggle with inadequate waste management infrastructure and rising environmental concerns.

In addition, the increasing adoption of circular economy principles worldwide presents a favorable environment for continuous tire pyrolysis plants. As businesses and governments seek to reduce their carbon footprint and improve waste recycling practices, pyrolysis technology offers a practical and scalable solution to these challenges.

Future Prospects and Challenges

While the market potential for continuous tire pyrolysis equipment is undeniably promising, there are certain challenges that need to be addressed. For one, the initial investment cost for establishing a pyrolysis plant can be significant, requiring careful financial planning and access to capital. Moreover, tire supply logistics must be well-managed to ensure a consistent feedstock for the plant.

Nevertheless, as the technology matures and economies of scale come into play, the cost of implementation is expected to decrease, making tire pyrolysis more accessible to a wider range of businesses. Governments’ growing focus on environmental policies and sustainable waste management is likely to drive demand further, creating a favorable climate for continued market growth.

Comments